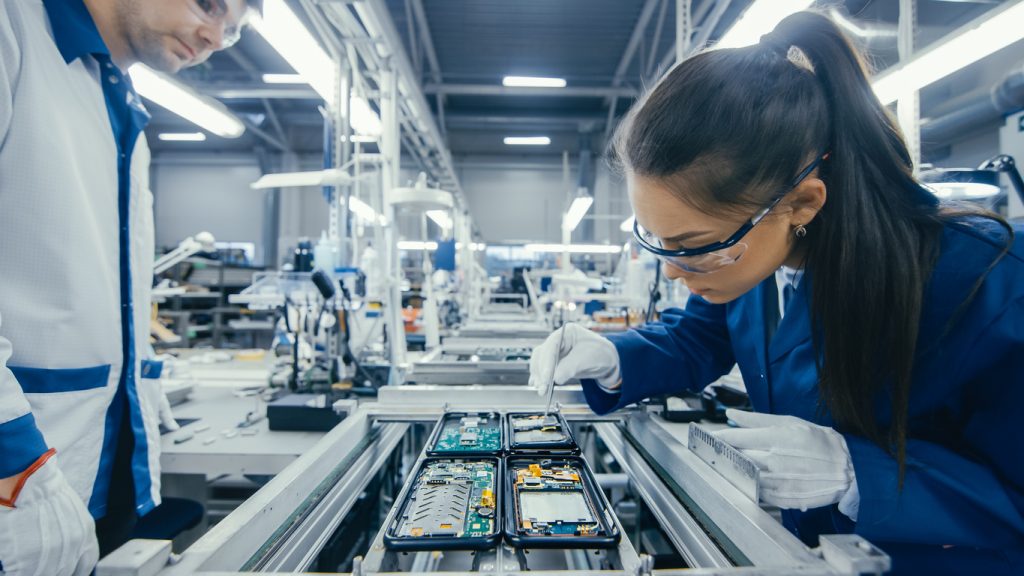

The assembly line is a testament to human ingenuity, transforming how products are made and revolutionizing industries.

At Kaminskiy Commercial Construction, a local commercial tenant improvement company, we pride ourselves on designing and optimizing assembly lines that cater to the unique demands of San Diego’s vibrant commercial sector.

Our approach ensures that every assembly line we craft not only enhances production efficiency but also aligns with the specific goals and values of your business.

San Diego, with its bustling commercial scene, requires assembly lines that are both efficient and adaptable. Our designs ensure that your production processes are streamlined, reducing lead times and maximizing output.

An assembly line is more than just a series of workstations; it’s a carefully orchestrated dance of processes, technologies, and people. The efficiency of an assembly line can make or break a manufacturing operation, directly impacting profitability and market competitiveness.

In the heart of San Diego’s commercial sector, the demand for rapid, efficient production is ever-present. Our assembly line solutions are crafted to meet these demands, ensuring businesses can keep pace with market dynamics and stay ahead of competitors.

Kaminskiy Commercial Construction offers a wide range of manufacturing renovation and construction services to assist you at every step of the Assembly Line Improvement process, from design to completion:

The assembly line is a complex ecosystem, and even minor inefficiencies can lead to significant operational challenges. Kaminskiy Commercial Construction has identified and addressed many problems businesses face in San Diego.

Here’s a look at the most prevalent assembly line challenges we tackle:

Kaminskiy Commercial Construction’s solutions address these assembly line challenges head-on, ensuring businesses in San Diego remain competitive and efficient. Our in-depth understanding of the intricacies of assembly line operations enables us to craft designs that are both innovative and practical.

By addressing these problem areas, we empower businesses to achieve heightened efficiency, quality, and profitability. Together, let’s revolutionize your assembly line, making it a pinnacle of modern manufacturing.

We conduct comprehensive assessments to understand your current setup and then collaborate with technology providers for seamless integration. Our approach ensures that new technologies enhance existing operations without causing significant disruptions, maintaining continuity while upgrading capabilities.

Absolutely. Our designs are tailored to meet the specific production requirements of diverse products. We focus on precision and efficiency, ensuring that specialized products are handled appropriately throughout the assembly process, from start to finish.

Worker safety is a critical focus in our designs. We include wide aisles for easy movement, clear safety signage, emergency exits, and ergonomic workstations to reduce strain. These features collectively create a safer work environment, minimizing the risk of accidents and enhancing overall safety.

We prioritize sustainability by integrating eco-friendly materials, energy-efficient technologies, and waste-reduction strategies. This approach helps in minimizing the environmental footprint of the assembly line, aligning with green manufacturing practices.

Our assembly line designs are inherently flexible and modular. They can be easily reconfigured or expanded to accommodate future changes in production processes, product types, or technological advancements, ensuring long-term utility and adaptability.

We design for optimized workflow by strategically placing workstations, equipment, and material handling systems. This reduces unnecessary movement, streamlines production processes, and enhances overall efficiency, leading to faster production times and reduced operational costs.

The assembly line is a cornerstone of modern manufacturing, and its design and efficiency can significantly influence a business’s success. With Kaminskiy Commercial Construction, you’re partnering with a team that understands the nuances of assembly line design and optimization. Let’s collaborate to craft a solution that positions your business for success in San Diego’s dynamic commercial landscape.